New FAM Centris® Slicer for almonds

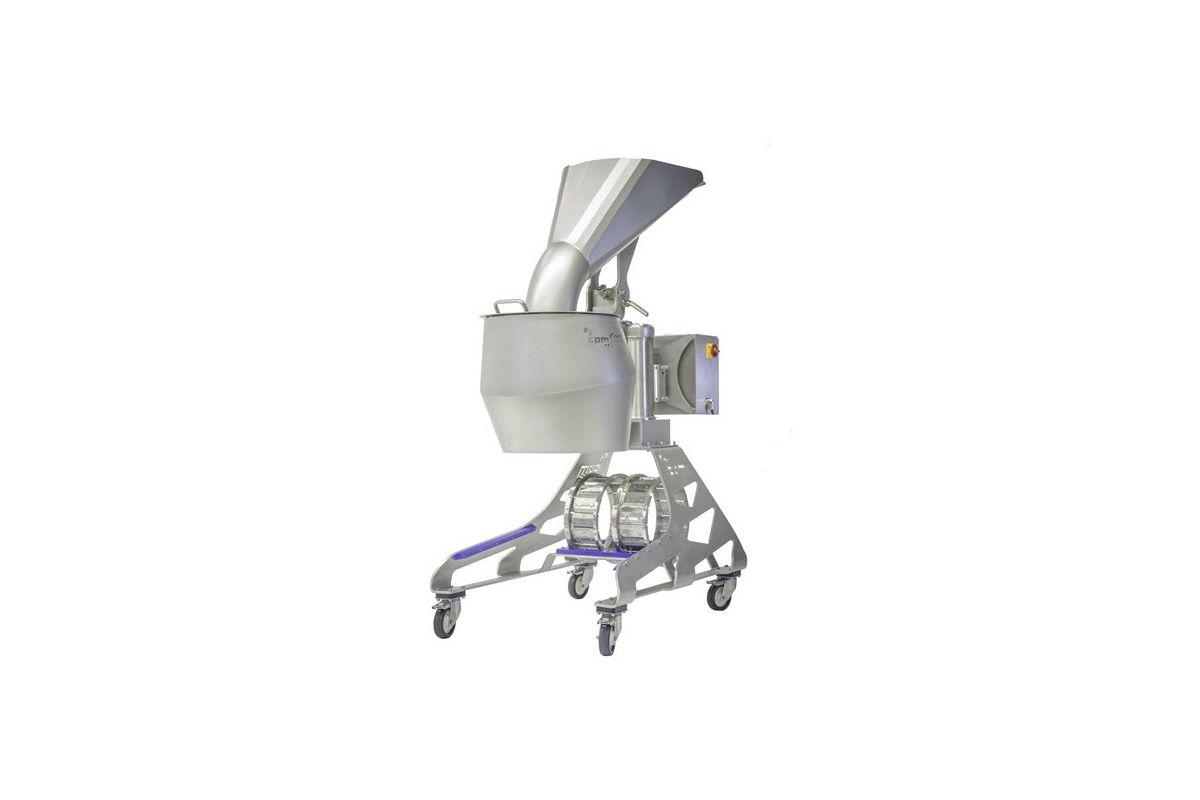

At BORRELL® we're very happy to announce the success of the new FAM Centris® M400 Slicer, special version for almonds and other nuts. It has been developed thanks to our partnership with FAM - STUMABO, manufacturers of advanced food cutting systems & high quality cutting blades.

This new machine is a unique due to its high capacity, reliability, high yields, hygienic construction, quick sanitation, easy adjustments and low maintenance and operation costs.

Some highlights and features, as follows:

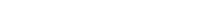

- Extremely precise centrifugal cutting principle with new and innovative patent pending cutting head technology.

- Different impellers available depending on the application.

- Impellers have round edges and vertical grooves to guide the product perfectly.

- The 100% stainless steel cutting head weighs 12 kg, has 16 cutting segments and a reduced amount of parts, which simplifies assembly.

- Unit can be positioned inline or as a stand-alone.

- Infeed provides uniform product flow to the cutting head and avoids overloading of the cutting head.

- Swivel infeed is an option.

- Trapped key interlocking safety system prevents access to the cutting area during machine operation.

- Rigid, seamless welded frame with no flat surfaces.

- Storage for two cutting heads underneath the machine and designed to fit eurobin.Equipped with a very robust and reliable Direct Drive System.

- No expensive gear box that requires continuous maintenance.

- Equipped with a 2.2 kW (3HP) motor AC three phase stainless steel motor for low energy consumption and designed for easy sanitation and washdown.

- Electrical control of the machine is start-stop without programming or read-outs in order to meet simplicity.

- Can be positioned at the back or at the side.

- Designed according to CE, FDA and HACCP regulations.

- The drive, product and electronics zone are completely separated.

- Continuous production of up to 2.000 Kg.h - 4.400 lb.h, approx. (whole meats clean from foreign aterial with a humidity range between 7% - 8% and advisable temperature of 75 C - 85 C / 167 F - 185 F).

We invite you to a demo and test! At BORRELL® facilities or we can arrange a custom demo for you in your production line